Carbon Capture, Storage And Utilization

We can help identify areas where experimental data might be necessary and then model the system to understand, among others:

- Maximum allowable water contents

- Minimum pressures and temperatures during the shutdown and subsequent restart of wells and pipelines

- Pressure and temperatures during depressurization and possible extend of the CO2 cloud

- Optimized pressure ranges during normal operation

- Effect of impurities in simulation accuracy and required safety margins

Carbon Capture, Storage And Utilization

We can help identify areas where experimental data might be necessary and then model the system to understand, among others:

- Maximum allowable water contents

- Minimum pressures and temperatures during the shutdown and subsequent restart of wells and pipelines

- Pressure and temperatures during depressurization and possible extend of the CO2 cloud

- Optimized pressure ranges during normal operation

- Effect of impurities in simulation accuracy and required safety margins

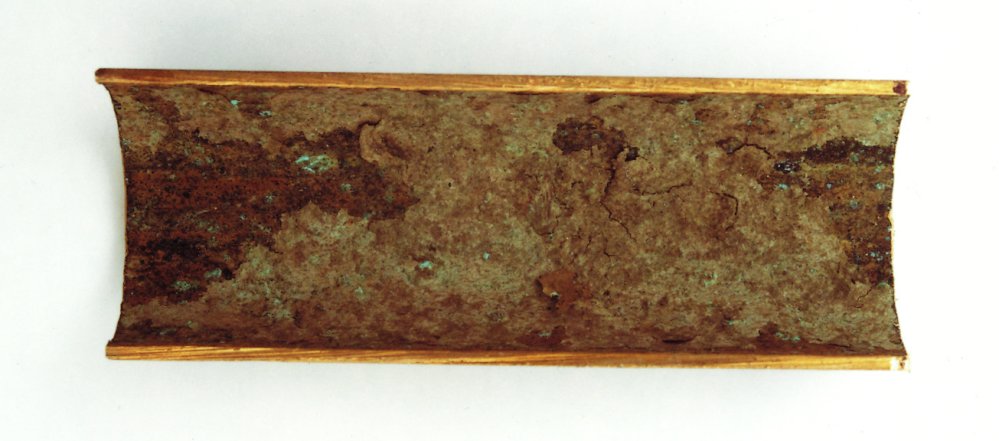

Wax and Asphaltene Studies

We offer a detailed analysis of asphaltenes and wax risks. We can help you:

- Determine the measurements needed to assess whether the fluids have a tendency for wax or asphaltene precipitation.

- If precipitation is a risk, understand where and when solids could pose a risk to production.

- Evaluate the severity of the risks using laboratory data, thermodynamics, and fluid hydraulics simulations.

- Based on risk severity, recommend the best management strategies and required intervention frequencies.

Wax and Asphaltene Studies

We offer a detailed analysis of asphaltenes and wax risks. We can help you:

- Determine the measurements needed to assess whether the fluids have a tendency for wax or asphaltene precipitation.

- If precipitation is a risk, understand where and when solids could pose a risk to production.

- Evaluate the severity of the risks using laboratory data, thermodynamics, and fluid hydraulics simulations.

- Based on risk severity, recommend the best management strategies and required intervention frequencies.

Feasibility and Concept Selection

We can help you assess the inherent risks of the system and provide a first range of solutions for each field development option. Specifically:

- Required laboratory analysis to determine the fluid characteristics: PVT tests, wax and asphaltene screening, emulsions, and foaming.

- Pressure and temperature boundaries and what they implied for the fluids: is wax a risk? Would hydrates form when the system cools down?

- Where and when would hydrates and other solids be a risk.

- Hydraulic analysis: line sizes, slug sizes, minimum turndowns, and minimum temperatures across the choke.

- Depressurization

- FA risks management options for each concept development option. List of pro and cons.

Feasibility and Concept Selection

We can help you assess the inherent risks of the system and provide a first range of solutions for each field development option. Specifically:

- Required laboratory analysis to determine the fluid characteristics: PVT tests, wax and asphaltene screening, emulsions, and foaming.

- Pressure and temperature boundaries and what they implied for the fluids: is wax a risk? Would hydrates form when the system cools down?

- Where and when would hydrates and other solids be a risk.

- Hydraulic analysis: line sizes, slug sizes, minimum turndowns, and minimum temperatures across the choke.

- Depressurization

- FA risks management options for each concept development option. List of pro and cons.

FEED

We can help you refine operational procedures and the required system characteristics to manage FA risks. Specifically:

- Minimum temperatures across choke during well restart and depressurization.

- Minimum turndowns and ramp-up procedures.

- Depressurization.

- Detailed hydrate management analysis.

- Wax and asphaltene remediation procedures.

FEED

We can help you refine operational procedures and the required system characteristics to manage FA risks. Specifically:

- Minimum temperatures across choke during well restart and depressurization.

- Minimum turndowns and ramp-up procedures.

- Depressurization.

- Detailed hydrate management analysis.

- Wax and asphaltene remediation procedures.

Operational Procedures

During production, we can help you make sure that planned operational procedures, such as shutdowns, restarts, acid jobs, solvent washes, and pipeline replacements, do not introduce any flow assurance risks in the system. We will check whether the system enters the hydrate region, if wax gelling is a risk, if there are any risks of asphaltene incompatibility, etc. After the analysis, we can recommend alternatives that will help diminish those risks.

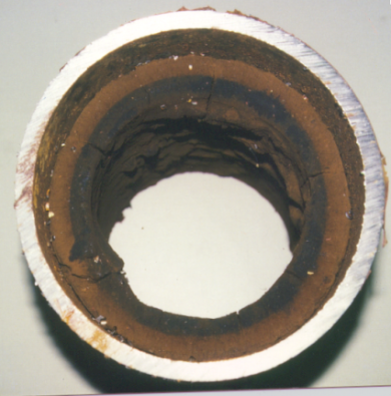

Solid Identification

When solids are recovered from pipelines, wells, or facilities, we can help you determine laboratory analysis required to identify the main components of the solids. Once the solid is identified, the best remediation option can be identified and deployed.

Operational Procedures

During production, we can help you make sure that planned operational procedures, such as shutdowns, restarts, acid jobs, solvent washes, and pipeline replacements, do not introduce any flow assurance risks in the system. We will check whether the system enters the hydrate region, if wax gelling is a risk, if there are any risks of asphaltene incompatibility, etc. After the analysis, we can recommend alternatives that will help diminish those risks.

Solid Identification

When solids are recovered from pipelines, wells, or facilities, we can help you determine laboratory analysis required to identify the main components of the solids. Once the solid is identified, the best remediation option can be identified and deployed.

Flow Assurance Reviews

We will provide you with an independent, unbiased review of the Flow Assurance work for your system. Specifically:

- Review of Flow Assurance reports.

- Review of design robustness to manage FA risks.

- Assistance to review required EPC scope of work.

- Review of required laboratory analysis and/or laboratory results.

- Review of solid identification work.

- Review operational procedures to check for their robustness to manage FA risks.

Flow Assurance Reviews

We will provide you with an independent, unbiased review of the Flow Assurance work for your system. Specifically:

- Review of Flow Assurance reports.

- Review of design robustness to manage FA risks.

- Assistance to review required EPC scope of work.

- Review of required laboratory analysis and/or laboratory results.

- Review of solid identification work.

- Review operational procedures to check for their robustness to manage FA risks.

EN

EN ES

ES